Essential Questions About Product Specifications and Customization

Machinery Capabilities and Compatibility

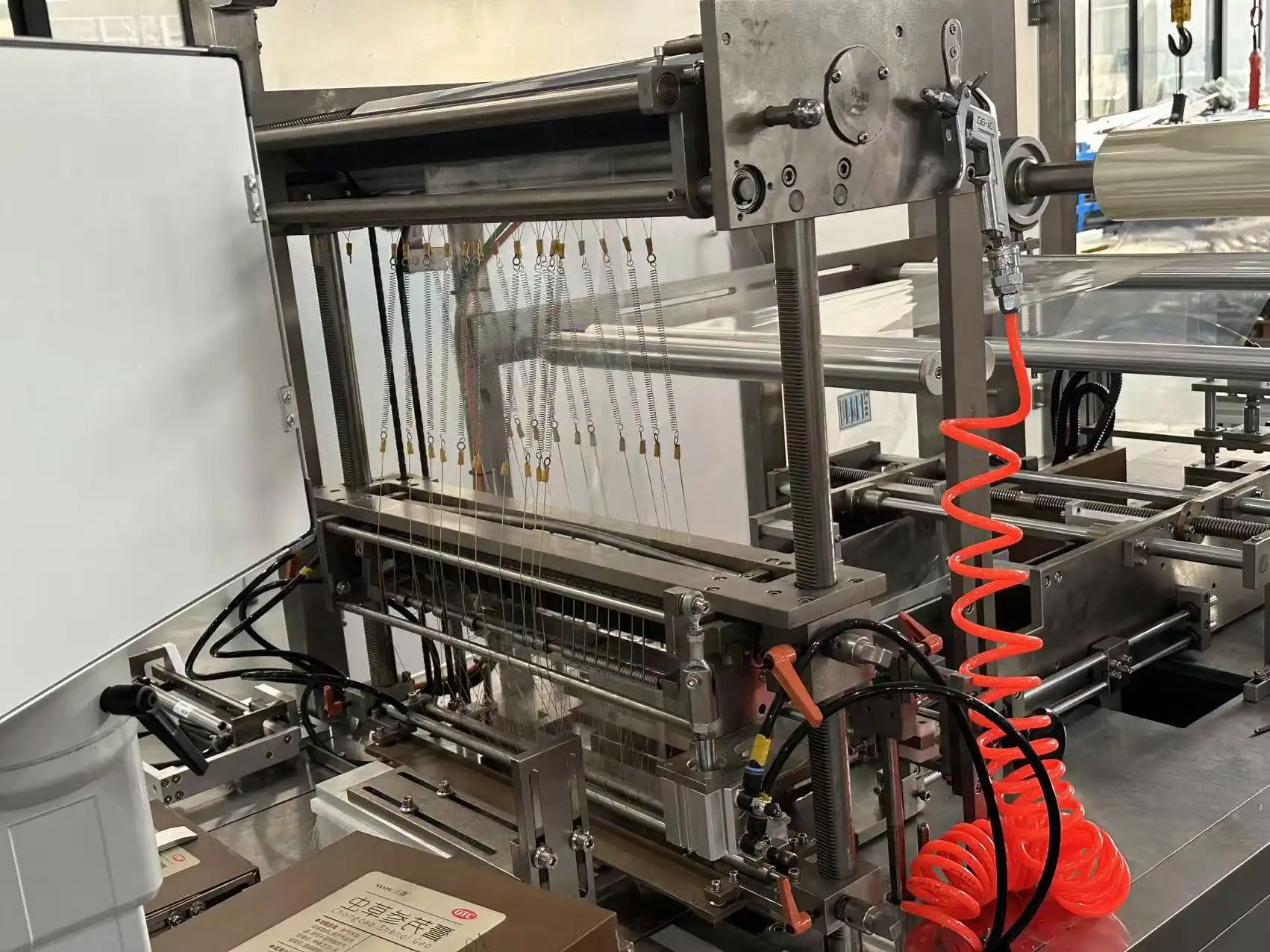

When evaluating packaging equipment, it's imperative to understand the machinery's capabilities and how well it aligns with your specific requirements. Ask your supplier about the types of materials the equipment can handle, its speed and output capacity, and whether it's compatible with your existing production line. Inquire about the machine's versatility in terms of package sizes and formats it can accommodate. This information will help you determine if the equipment can meet your current needs and adapt to future production demands.

Customization Options

Every business has unique packaging needs, so it's crucial to explore customization possibilities. Ask your supplier about available modifications or add-ons that can tailor the equipment to your specific products or processes. Discuss options for integrating special features, such as date coding, labeling systems, or quality control mechanisms. A supplier who offers flexibility in customization can provide solutions that precisely match your packaging requirements and potentially improve your overall efficiency.

Compliance and Certification

Ensuring that the packaging equipment meets industry standards and regulatory requirements is paramount. Inquire about relevant certifications, such as CE marking for European markets or cGMP compliance for pharmaceutical applications. Ask about the supplier's adherence to ISO standards and their commitment to quality assurance. This information not only guarantees the equipment's safety and reliability but also ensures that your packaging processes comply with industry regulations.

Critical Inquiries About Maintenance and Support

Preventive Maintenance Protocols

Regular maintenance is essential for keeping packaging equipment in optimal condition and preventing unexpected downtime. Ask your supplier about recommended maintenance schedules and procedures. Inquire about the availability of maintenance manuals, training programs for your staff, and whether the supplier offers preventive maintenance services. Understanding these aspects will help you plan for long-term equipment care and minimize potential disruptions to your production.

Spare Parts Availability

The availability of spare parts is crucial for minimizing downtime in case of equipment failure. Ask your supplier about their inventory of spare parts, typical lead times for ordering components, and whether they offer emergency part delivery services. Inquire about the expected lifespan of critical components and any recommendations for keeping a stock of essential spare parts on-site. This information will help you develop a proactive approach to equipment maintenance and repairs.

Technical Support and Service Agreements

Comprehensive technical support is vital for addressing issues promptly and maintaining equipment performance. Ask about the supplier's technical support offerings, including remote diagnostics, on-site service, and response times for emergency calls. Inquire about service agreement options, warranty terms, and the availability of extended warranty packages. Understanding the level of support you can expect will help you assess the total cost of ownership and ensure you have adequate assistance when needed.

Financial Considerations and Long-term Partnership

Total Cost of Ownership

While the initial purchase price of the packaging equipment is important, it's equally crucial to consider the total cost of ownership over the equipment's lifespan. Ask your supplier for a detailed breakdown of operational costs, including energy consumption, maintenance expenses, and consumables. Inquire about the expected return on investment and any case studies or testimonials from similar businesses that have implemented the equipment. This comprehensive financial perspective will help you make a more informed decision and budget accurately for the long term.

Financing Options and Payment Terms

Understanding the available financing options can help you manage your capital expenditure more effectively. Ask your supplier about leasing programs, installment plans, or other financing solutions they offer. Inquire about payment terms, deposits required, and any discounts available for early or bulk payments. Discussing these financial aspects upfront can help you structure a deal that aligns with your company's financial strategy and cash flow requirements.

Future Support and Upgrades

As your business grows and technology evolves, your packaging needs may change. Ask your supplier about their commitment to ongoing research and development, and how they support customers with equipment upgrades or additions to existing lines. Inquire about their approach to integrating new technologies or features into older models. A supplier who demonstrates a long-term vision and willingness to support your future growth can be a valuable partner in your business journey.

Conclusion

Selecting the right packaging equipment supplier is a critical decision that can significantly impact your business operations and product quality. By asking these comprehensive questions, you'll gain valuable insights into the supplier's capabilities, commitment to quality, and long-term support. Remember that a reputable supplier should be transparent, responsive, and eager to demonstrate how their equipment can benefit your specific needs. Take the time to thoroughly evaluate potential suppliers, and don't hesitate to request demonstrations or references from existing customers.

Contact Us

Ready to explore high-quality packaging solutions tailored to your needs? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] to discuss how our innovative equipment can enhance your packaging processes and drive your business forward.