The Evolution of Pharmaceutical Packaging Technology

Traditional Packaging Methods and Their Limitations

Historically, pharmaceutical companies relied on manual packaging processes or rudimentary automation. These methods were time-consuming, prone to human error, and struggled to meet the increasing demand for medications. Quality control was challenging, and product consistency varied significantly between batches. In addition, manual systems lacked the ability to ensure proper sealing, tamper evidence, and compliance with evolving regulatory standards. As production volumes grew, manufacturers faced higher risks of contamination, delays, and inefficiencies, underscoring the urgent need for advanced blister packaging technologies.

The Advent of Blister Packaging Machines

The introduction of blister packaging machines marked a pivotal moment in pharmaceutical manufacturing. These innovative devices offered a more hygienic, efficient, and reliable method for packaging pills and capsules. The technology allowed for precise dosage control and tamper-evident packaging, addressing key concerns in medication safety. Beyond improving product integrity, blister machines also enhanced supply chain efficiency, extended shelf life through better protection against moisture and contamination, and provided clear labeling for patients, greatly improving compliance and overall healthcare outcomes.

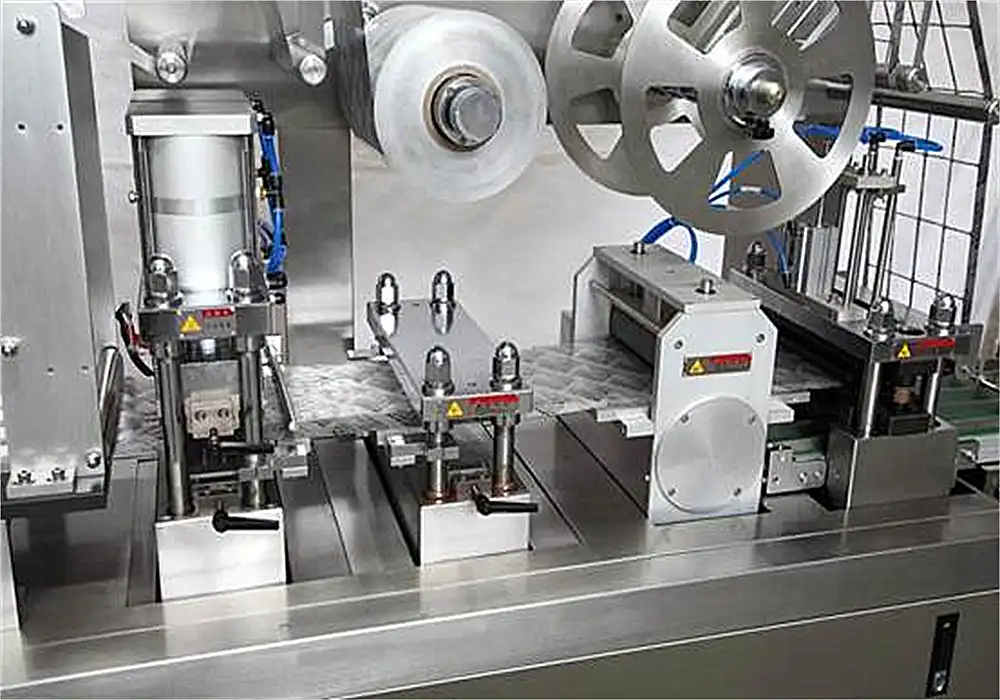

Technological Advancements in Blister Packaging

Modern blister packaging machines incorporate state-of-the-art features such as high-speed production capabilities, advanced sealing technologies, and integrated quality control systems. These enhancements have further improved the efficiency and reliability of pharmaceutical packaging processes. In addition, modern systems support flexible configurations to handle different blister formats and eco-friendly materials, aligning with sustainability goals. With automated inspection and data tracking, manufacturers are reducing waste, ensuring regulatory compliance, and enhancing patient safety while meeting the growing global demand for high-quality medications.

Impact on Pharmaceutical Supply Chain Efficiency

Streamlined Production Processes

Blister packaging machines have revolutionized pharmaceutical manufacturing by significantly increasing production speed and efficiency. Automation reduces reliance on manual labor, ensuring consistent output even during high-demand periods. The standardized process minimizes human errors, such as miscounting or misalignment of products, which can compromise quality. By streamlining production workflows, pharmaceutical companies can better meet market demands, shorten lead times, and optimize resource allocation. This enhanced efficiency ultimately supports cost savings and strengthens competitiveness in a fast-paced, high-volume industry.

Enhanced Quality Control Measures

Advanced blister packaging systems incorporate integrated inspection technologies that automatically verify the integrity of each blister pack. These systems detect issues such as missing doses, damaged blisters, or misprinted labels, ensuring compliance with strict regulatory standards. Automated quality control reduces defect rates and the likelihood of costly product recalls, while enhancing patient safety. By consistently delivering high-quality packaging, manufacturers maintain brand reputation, build trust with distributors and patients, and ensure that medications are protected from contamination, moisture, and other environmental factors throughout the supply chain.

Improved Inventory Management

The precision of blister packaging enables more accurate inventory tracking and management across the pharmaceutical supply chain. Each blister pack contains a predetermined number of doses, allowing for easier stock monitoring and planning of reorder points. This precise control reduces waste due to product expiration, damage, or misplacement and improves forecasting accuracy. Pharmacies, distributors, and manufacturers can better align supply with demand, ensuring that products are available when needed while minimizing overstock. Improved inventory management also enhances operational efficiency and contributes to cost savings throughout the supply chain.

Benefits to Stakeholders Across the Supply Chain

Advantages for Pharmaceutical Manufacturers

Pharmaceutical manufacturers benefit greatly from the adoption of blister packaging machines, experiencing substantial improvements in efficiency and cost management. Automation reduces the need for manual labor, allowing teams to focus on other value-added activities. Material waste is minimized through precise filling and sealing, lowering overall production costs. These efficiency gains, combined with higher output and consistent product quality, contribute to increased profit margins. In addition, manufacturers can respond more effectively to market demand, enhancing competitiveness and supporting growth in a rapidly evolving pharmaceutical landscape.

Improvements for Distributors and Pharmacies

Distributors and pharmacies gain multiple operational advantages from blister packs, primarily due to their compact and organized design. The standardized layout simplifies storage, stacking, and transportation, optimizing space utilization in warehouses and retail settings. Clear labeling on each pack reduces errors during handling, shipping, and dispensing, improving safety and regulatory compliance. By facilitating accurate distribution and easy access to medication, blister packaging streamlines supply chain operations, enhances operational efficiency, and ensures that end-users receive products in a safe, organized, and reliable manner.

Enhanced Patient Experience and Compliance

For patients, blister packs provide convenience and ease of use, supporting better medication adherence and improved health outcomes. The clear organization of individual doses allows patients to follow complex medication regimens with minimal confusion. Integrated labeling and, in some designs, calendar-style arrangements help track daily intake and prevent missed or duplicate doses. By improving patient engagement and adherence, blister packs not only enhance the overall user experience but also support more effective treatment, contribute to better health results, and strengthen the trust between patients and healthcare providers.

Conclusion

The integration of blister packaging machines into pharmaceutical supply chains has yielded substantial improvements in efficiency, quality, and safety. These technological advancements have not only streamlined manufacturing processes but also enhanced the entire distribution network, ultimately benefiting patients through improved medication management. As the pharmaceutical industry continues to evolve, blister packaging machines will likely play an increasingly vital role in ensuring the safe and efficient delivery of medications to consumers worldwide.

FAQs

What are the main advantages of blister packaging machines in pharmaceutical production?

Blister packaging machines offer increased efficiency, improved quality control, better product protection, and enhanced patient compliance.

How do blister packaging machines contribute to patient safety?

They provide tamper-evident packaging, precise dosage control, and clear labeling, reducing the risk of medication errors and contamination.

Can blister packaging machines handle different types of medications?

Yes, modern blister packaging machines are versatile and can be configured to package various forms of solid oral medications, including tablets and capsules.

Transform Your Pharmaceutical Packaging with Haichina

As a leading packaging equipment manufacturer, Haichina offers state-of-the-art blister packaging machines tailored to pharmaceutical industry needs. Our CE and cGMP-certified solutions combine high-speed operation with precision and reliability. With customizable options and comprehensive training services, we ensure your packaging line operates at peak efficiency. Experience the benefits of our innovative technology and expert support. Contact us at [email protected] to elevate your pharmaceutical packaging process.

References

Johnson, M. (2022). Advancements in Pharmaceutical Packaging: A Comprehensive Review. Journal of Pharmaceutical Technology, 45(3), 112-128.

Smith, A., & Brown, B. (2021). The Impact of Blister Packaging on Medication Adherence: A Meta-Analysis. American Journal of Health-System Pharmacy, 78(15), 1389-1402.

Thompson, C. (2023). Supply Chain Optimization in the Pharmaceutical Industry: Case Studies and Best Practices. International Journal of Logistics Management, 34(2), 245-260.

Garcia, R., et al. (2020). Quality Control in Pharmaceutical Packaging: The Role of Automated Inspection Systems. Pharmaceutical Engineering, 40(4), 30-42.

Lee, S., & Park, J. (2022). Sustainability in Pharmaceutical Packaging: Innovations and Challenges. Journal of Cleaner Production, 330, 129751.

Wilson, D. (2021). The Economic Impact of Advanced Packaging Technologies in the Pharmaceutical Sector. Health Economics Review, 11(1), 1-15.