The Role of Blister Cartoning Machine in the Pharmaceutical

The pharmaceutical sector depends upon accuracy, sterility, and speed. A blister cartoning machine unites these three imperatives by transferring sealed blister packs into secondary cartons with flawless synchronization. Beyond simple boxing, this equipment safeguards drug efficacy, amplifies traceability, and drives line efficiency. From over-the-counter analgesics to high-potency oncology therapies, blister cartoners shelter tablets and capsules during transit, simplify serialisation, and satisfy stringent cGMP guidelines. In practical terms, the machine bridges primary blister packaging and tertiary logistics, forming a critical node that keeps global supply chains dependable and compliant.

Engineering Precision: How Blister Cartoning Elevates Pharmaceutical Integrity?

Protecting Active Ingredients

Sensitive molecules dislike moisture, oxygen, and mechanical shock. While the initial blister cavity defends the dosage, the external carton creates an extra micro-environment that buffers vibrations, light, and accidental puncture. A high-speed blister cartoning machine folds, tucks, and glues with millimetric consistency, so every carton replicates the same protective geometry. Uniform compression prevents crushing, yet avoids excessive stress on the blister web. Zhejiang Haizhong Machinerys servo-driven cartoners employ adaptive torque control; cartons receive just enough force to close securely without warping. This persistence in dimensional accuracy preserves dissolution rates, potency, and ultimately therapeutic value.

Streamlining Batch-to-Box Traceability

Pharmacovigilance hinges on knowing which blister belongs to which batch. Modern blister cartoning machines integrate vision inspection and smart conveyor singulation that marry blister codes with carton IDs in real time. A single scan at the pallet stage reveals the entire genealogy: raw material lot, blistering parameters, cartoning timestamp, pallet number. Such nested data cuts recall windows from days to minutes and thwarts counterfeit diversion. When connected to MES or ERP platforms, the blister cartoning machine's database enriches OEE dashboards and informs preventive maintenance. The result is transparent, data-centric manufacturing that regulators praise and patients trust.

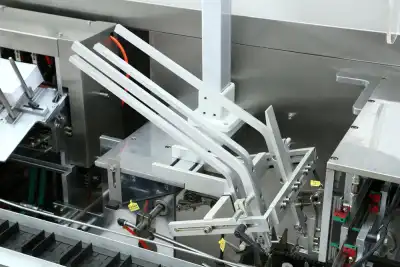

Minimising Human Touchpoints

Hands introduce particulates, miscounts, and microbiological risks. Automated feeding magazines align blisters, leaflets, and cartons, while robotic pick-and-place arms eliminate manual kitting. Operators supervise through HMI interfaces instead of repetitive handling. Reduced contact lowers cross-contamination probability and ergonomic strain. Haizhongs balcony design further isolates the drive train from the product path, simplifying dry-wipe sanitisation and slashing line clearance time between APIs. Fewer touchpoints translate to fewer deviations, shorter audits, and a calmer production floor.

Regulatory Alignment and Compliance Edge

cGMP Harmonisation

Authorities worldwide - FDA, EMA, CFDA - mandate that packaging systems be cleanable, durable, and thoroughly documented. A blister cartoning machine engineered under CE and ISO 9001 schematics, like those from Zhejiang Haizhong Machinery, arrives with material certificates, weld maps, and surface-roughness logs. Stainless steel frames shrug off aggressive sanitising agents, and sloped surfaces deter standing water. During qualification, Installation (IQ) and Operational (OQ) protocols validate temperature stability of glue guns, feeder accuracy, and reject efficiency above 99.8 %. This harmonised design shortens the path to regulatory approval in multiple jurisdictions simultaneously.

Serialization-Ready Architecture

Governments now demand unique identifiers on each saleable unit to combat counterfeit drugs. Camera-guided inkjet or laser coders mount effortlessly on the cartoners outfeed, applying 2D DataMatrix codes plus human-readable text. Synced PLC logic cross-checks printed data with upstream blister codes, rejecting any mismatch automatically. Aggregation modules then compile carton IDs into bundle and case barcodes, storing encrypted records for up to ten years. With serialization baked in, plants avoid costly retrofits when legislation tightens.

Validation & Documentation Benefits

Continuous, audited data streams emanating from the blister cartoning machines sensors create robust validation trails. Torque curves of tuck-flap closers, vacuum pressures on leaflet pickers, and scan logs of inspector cameras populate electronic batch records (eBR). Auditors can filter by shift, SKU, or feeder pocket. This granularity curtails the need for manual logbooks and expedites deviation investigations. When a parameter drifts, alarm hierarchies escalate from local HMI prompts to plant-wide alerts, fostering proactive rather than reactive compliance.

Operational ROI for Modern Plants

Accelerated Time-to-Market

Drug launches often hinge on packaging readiness. Modular blister cartoning machines offer fast changeover - often under 15 minutes - through recipe-driven servo positioning and tool-less guide rails. Brand teams can pivot from 10-count to 30-count cartons without machining new parts, releasing clinical trial batches swiftly. Coupled with line speeds surpassing 300 cartons per minute, revenue begins accruing sooner, reinforcing a competitive moat.

Energy and Material Conservation

Sustainability imperatives demand leaner resource use. Servo motors consume energy only during motion phases, unlike pneumatic counterparts that bleed compressed air constantly. Precision glue spray nozzles deposit exact beads, trimming hot-melt usage by up to 25 %. Carton blank optimisation, supported by CAD nesting algorithms, yields narrower flaps and shorter dust tabs, lightening board weight without sacrificing integrity. Over a yearly horizon, these economies can fund ancillary equipment - checkweighers, case packers, palletisers - propelling a virtuous investment cycle.

Scalability for Diverse Form Factors

The pharmaceutical universe is no longer tablet-centric. Oro-dispersible films, transdermal patches, and combo kits demand creative secondary packaging. A future-proof blister cartoning machine anticipates that diversity with interchangeable feeders: bucket conveyors for suppositories, rotary placers for auto-injectors, and collators for wallet packs. Zhejiang Haizhong Machinery leverages open-source PLC languages and modular I/O, letting integrators bolt on new stations without rewriting entire control logic. Plants can thus court new contract-manufacturing clients or pivot to emerging therapies while retaining the same capital asset.

Conclusion

A blister cartoning machine does far more than insert blister packs into cardboard. It fortifies drug stability, stitches together traceability, delivers regulatory tranquility, and unlocks significant financial upside. Its intersection of mechanical finesse, digital intelligence, and hygienic design turns packaging from a cost centre into a strategic advantage.

Contact Us

For more information about our cutting-edge blister cartoning machines and how they can revolutionize your pharmaceutical packaging process, please contact us at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your specific needs.

References

Good Manufacturing Practice for Medicinal Products - European Medicines Agency, 2022.

Global Serialization Requirements for Prescription Drugs - GS1 Healthcare Technical Report, 2023.

Smith, J. & Delgado, P., Energy Optimisation in Servo-Driven Packaging Lines, Journal of Sustainable Manufacturing, 2021.

Kumar, R., Advanced Vision Inspection Systems for Pharmaceutical Packaging, Pharmaceutical Engineering Review, 2020.

U.S. FDA, Data Integrity and Compliance With cGMP Guidance, 2024 Revision.

Zhang, L. & Hsu, T., Modular Automation Platforms in Secondary Packaging, International Journal of Pharmaceutical Technology, 2022.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?