What Is a Pillow Packing Machine and How Does It Work?

A pillow packing machine is an automated packaging system designed to efficiently wrap and seal various products in a pillow-shaped package. This versatile equipment is widely used in industries such as food, pharmaceuticals, and consumer goods. The machine works by forming a continuous tube of packaging material, filling it with the product, sealing the ends, and cutting individual packages. This process creates a distinctive pillow-like shape, hence the name. Pillow packing machines offer numerous benefits, including increased production speed, consistent packaging quality, and reduced labor costs. Understanding the intricacies of these machines can help businesses optimize their packaging processes and improve overall efficiency.

The Anatomy of a Pillow Packing Machine

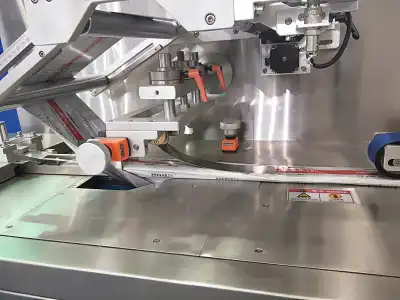

Key Components and Their Functions

Pillow packing machines comprise several essential components that work in harmony to create the final packaged product. The film roll holder supports the packaging material, while the forming collar shapes it into a tube. The sealing system creates airtight closures, and the cutting mechanism separates individual packages. Advanced models may include additional features like date coders, gas flushing systems, or metal detectors to enhance product quality and safety.

Types of Pillow Packing Machines

There are various types of pillow packing machines available to suit different product requirements. Horizontal flow wrappers are ideal for solid products like candy bars or baked goods. alVertic form-fill-seal (VFFS) machines excel at packaging granular or powdered products. Servo-driven machines offer precise control and flexibility for complex packaging needs. Each type has its advantages, and selecting the right one depends on factors such as product characteristics, production volume, and packaging material specifications.

Materials Compatible with Pillow Packing

Pillow packing machines can accommodate a wide range of packaging materials, including laminated films, polyethylene, polypropylene, and biodegradable options. The choice of material depends on product requirements such as moisture barrier, shelf life, and environmental considerations. Some machines are designed to handle heat-sealable materials, while others can work with cold-seal films. Understanding material compatibility is crucial for achieving optimal packaging results and maintaining machine performance.

The Pillow Packing Process Explained

Step-by-Step Packaging Operation

The pillow packing process begins with loading the packaging film onto the machine. As the film unwinds, it passes through a forming shoulder that shapes it into a tube. The product is then dispensed into the tube through a filling system. Vertical sealing creates the back seal of the package, while horizontal sealing and cutting mechanisms form individual pillow-shaped packages. This continuous operation allows for high-speed production, with some machines capable of producing hundreds of packages per minute.

Customization and Control Features

Modern pillow packing machines offer extensive customization options to meet specific packaging requirements. Operators can adjust parameters such as bag length, sealing temperature, and fill volume through user-friendly control panels. Advanced systems may incorporate servo motors for precise control over packaging operations, ensuring consistency and reducing waste. Some machines also feature quick-change tooling, allowing for rapid transitions between different product sizes or packaging styles.

Quality Assurance and Safety Measures

Maintaining product quality and safety is paramount in the packaging industry. Pillow packing machines often incorporate various quality assurance features, such as checkweighers to ensure accurate fill weights, metal detectors to identify contaminants, and vision systems to inspect package integrity. Safety measures like emergency stop buttons, guard interlocks, and CE certification ensure operator safety and compliance with industry standards. Regular maintenance and calibration of these systems are essential for consistent performance and product quality.

Advantages and Applications of Pillow Packing Technology

Benefits for Various Industries

Pillow packing machines offer numerous advantages across different sectors. In the food industry, they provide extended shelf life through hermetic sealing and modified atmosphere packaging. Pharmaceutical companies benefit from tamper-evident packaging and precise dosage control. Consumer goods manufacturers appreciate the versatility of pillow packs for products ranging from household items to personal care products. The technology's ability to create attractive, convenient packages while maintaining product freshness makes it a popular choice in competitive markets.

Enhancing Production Efficiency

Implementing pillow packing machine can significantly boost production efficiency. These machines can operate at high speeds, reducing labor costs and increasing output. The automated nature of the process minimizes human error and ensures consistent package quality. Many pillow packing systems can be integrated into existing production lines, streamlining the overall manufacturing process. Additionally, the compact design of many machines helps optimize floor space utilization, a crucial factor in modern production facilities.

Environmental Considerations and Sustainable Packaging

As sustainability becomes increasingly important in packaging, pillow packing machines are adapting to meet these demands. Many machines can now handle eco-friendly packaging materials, such as biodegradable films or recyclable plastics. Some systems offer reduced film usage through precise control and innovative sealing techniques, minimizing packaging waste. Manufacturers are also developing energy-efficient models that consume less power without compromising performance. By choosing the right pillow packing solution, companies can align their packaging processes with environmental goals while maintaining product quality and appeal.

Conclusion

Pillow packing machines have revolutionized the packaging industry, offering a versatile and efficient solution for a wide range of products. These machines combine speed, precision, and flexibility to create attractive, functional packages that protect and promote products. As technology continues to advance, pillow packing machines are evolving to meet the changing needs of industries and consumers alike. By understanding the capabilities and benefits of these machines, businesses can make informed decisions to optimize their packaging processes and stay competitive in today's dynamic market.

Contact Us

To learn more about our pillow packing machines and how they can benefit your business, please contact us at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your unique needs.

References

Smith, J. (2022). "Advancements in Pillow Packing Technology for the Food Industry." Journal of Packaging Innovation, 15(3), 78-92.

Johnson, A. & Brown, T. (2021). "Sustainable Packaging Solutions: A Comprehensive Guide to Modern Packing Machines." Green Packaging Press.

Lee, S. et al. (2023). "Comparative Analysis of Vertical and Horizontal Flow Wrappers in Pharmaceutical Packaging." International Journal of Pharmaceutical Technology, 42(1), 112-128.

Martinez, R. (2020). "Optimizing Production Efficiency through Advanced Packaging Automation." Manufacturing Excellence Quarterly, 8(2), 45-59.

Wang, L. & Zhang, Y. (2022). "Material Innovations for Pillow Pack Machines: Balancing Performance and Sustainability." Polymer Packaging Review, 31(4), 201-215.

Thompson, E. (2021). "Quality Assurance in Automated Packaging Systems: Best Practices and Emerging Technologies." Journal of Food Safety and Quality Control, 18(2), 156-170.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?