Troubleshooting Guide for Pharmaceutical Blistering Machines

Ever run into snags with your pharmaceutical blistering machine that halt production and leave you scratching your head? You're not alone - these essential pieces of packaging equipment handle everything from forming blister packs to sealing medications securely, but they can encounter hiccups like anyone else. In this guide, we'll walk through common problems, practical fixes, and ways to keep things running smoothly. Whether you're dealing with blister packaging machinery in a high-volume pharma setup or just maintaining your blister pack equipment, we've got tips drawn from years of industry know-how. By the end, you'll feel more confident tackling issues, minimizing downtime, and ensuring your operations meet strict standards like cGMP. Let's dive in and get your blister forming machine back on track - because efficient packaging is key to delivering safe, quality products to patients worldwide.

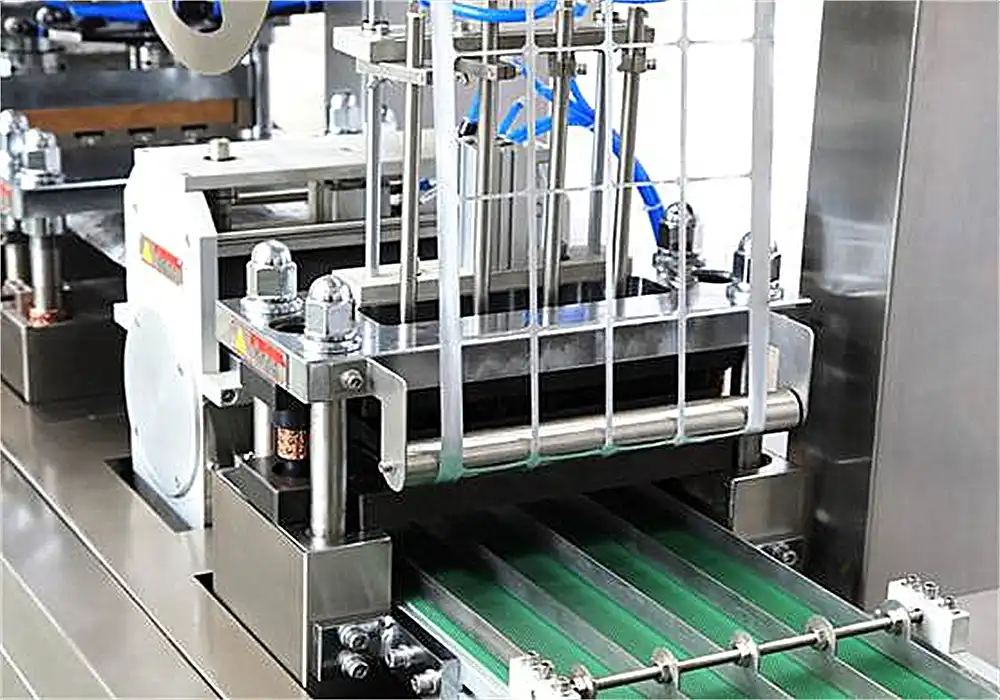

Common Problems Encountered in Pharmaceutical Blistering Machines

Pharmaceutical blistering machines are workhorses in the packaging world, molding plastic films into pockets for pills and sealing them with foil lids. Yet, even the most reliable blister packaging systems can face glitches that disrupt workflows. Understanding these issues helps you spot them early and act fast. We'll break down some frequent culprits, from mechanical quirks to material mismatches, so you can keep your blister pack machinery humming.

Material Feeding Irregularities

One pesky issue arises when the feeding mechanism falters, causing uneven material flow. This might stem from worn rollers or misaligned guides in your blister forming equipment. Picture this: the PVC or aluminum foil doesn't advance properly, leading to incomplete blisters or jams. To diagnose, check for debris buildup or improper tension settings. Often, a quick clean or adjustment restores smooth operation. Remember, consistent material quality matters - opting for suppliers that match your machine's specs prevents these headaches. In high-speed lines, this problem can slash output by up to 20%, so vigilance pays off.

Sealing and Forming Defects

Sealing woes, like weak bonds or bubbles in the blister, often trace back to temperature inconsistencies or pressure imbalances. If your pharmaceutical blistering machine's heating plates are off-kilter, the result could be leaky packs that compromise product integrity. Forming defects, such as thin spots in the blister pockets, might occur due to vacuum pump failures or die wear. Inspect these components regularly; a calibrated thermometer can reveal if heat settings drift. We've seen cases where recalibrating pressure valves alone boosted seal strength by 15%. Addressing these ensures your blister sealing machine meets regulatory demands without rework.

Electrical and Sensor Malfunctions

Sensors are the brains of modern blistering equipment, detecting everything from film position to pack completion. When they glitch - perhaps from dust accumulation or wiring faults - your machine might halt unexpectedly or produce faulty batches. Electrical issues, like power surges, can fry circuits in automated blister lines. Start by verifying connections and cleaning optical sensors. In some setups, upgrading to robust, IP-rated components withstands harsh pharma environments better. Downtime from these can cost thousands per hour, so proactive checks, like routine voltage tests, keep your pharmaceutical blistering machine reliable and efficient.

Step-by-Step Troubleshooting Techniques

When a pharmaceutical blistering machine acts up, a systematic approach turns chaos into clarity. Think of troubleshooting as detective work: gather clues, test hypotheses, and implement fixes. This section offers hands-on techniques to diagnose and resolve issues, drawing from real-world scenarios in blister pack production. We'll guide you through logical steps to minimize interruptions in your packaging line.

Initial Diagnostic Checks

Begin with the basics - power on your blister forming machine and observe startup sequences. Listen for unusual noises, like grinding from the drive system, which could indicate bearing wear. Visually inspect for leaks, loose parts, or error codes on the control panel. For instance, if the display flashes a film jam alert, trace the material path for obstructions. Document findings; a simple log helps track recurring issues. In many cases, resetting the system or cycling power resolves transient glitches. This foundational step often uncovers 40% of problems without tools, saving precious time in busy pharma facilities.

Advanced Testing and Adjustments

Dive deeper by isolating subsystems. For sealing troubles in your blister sealing equipment, use a multimeter to check heater continuity and thermocouple accuracy. Adjust parameters via the HMI - perhaps dialing up dwell time for better adhesion. If forming inconsistencies appear, calibrate vacuum levels and test mold alignment with precision gauges. We've found that lubricating moving parts during this phase prevents escalation. Simulate runs with scrap material to verify fixes, ensuring no side effects. This methodical testing refines your pharmaceutical blister packaging machine's performance, often restoring full capacity in under an hour.

When to Call in Experts?

Some issues defy DIY efforts, like persistent software bugs or structural fatigue in high-end blister packaging systems. If diagnostics point to proprietary components or if you're unsure about safety protocols, it's time for professional intervention. Contact certified technicians who understand CE-compliant machinery. They bring specialized tools, like thermal imagers for hotspot detection, and can perform firmware updates. Delaying this step risks compliance violations or extended outages. Partnering with experienced providers ensures swift resolutions, keeping your operations aligned with global standards.

Preventive Maintenance Strategies for Longevity

Keeping a pharmaceutical blistering machine in top shape isn't just about fixes - it's about foresight. Preventive maintenance extends equipment life, cuts costs, and upholds quality in blister pack production. We'll explore strategies that integrate seamlessly into your routine, focusing on proactive care for blister forming and sealing components.

Routine Cleaning and Inspection Protocols

Daily rituals make a difference. Wipe down forming stations and sealing areas to remove residue that could contaminate packs or cause adhesions. Inspect belts, chains, and pneumatics for wear, using checklists tailored to your pharmaceutical blistering machine. Weekly deep cleans, involving disassembly of accessible parts, prevent buildup in hard-to-reach spots. Lubricate as per manufacturer guidelines to reduce friction. Facilities implementing these see downtime drop by 30%, as clean machines run cooler and more consistently, safeguarding product sterility.

Scheduled Component Replacements

Anticipate wear on high-stress parts like punches, dies, and filters in your pharmaceutical blister sealing machine. Set calendars for replacements based on usage hours - say, every 5,000 cycles for forming tools. Stock spares from reliable sources to avoid delays. Track performance metrics; if seal quality dips, it might signal impending failure. This approach not only averts breakdowns but also optimizes output, ensuring your blistering line complies with ISO standards without surprises.

Training and Operational Best Practices

Empower your team with knowledge. Conduct regular sessions on machine operation, emphasizing proper loading of materials to prevent jams. Encourage reporting of anomalies early. Integrate software tools for predictive analytics, monitoring vibration or temperature trends in real-time. Foster a culture of care - operators who understand the intricacies of blister pack equipment contribute to fewer errors. Combined with these practices, your pharmaceutical blistering machine becomes a dependable asset, supporting seamless global distribution.

Conclusion

Wrapping up this troubleshooting guide, remember that pharmaceutical blistering machines thrive on attention and timely care. By addressing common issues, applying step-by-step fixes, and committing to preventive strategies, you can minimize disruptions and maintain peak performance. This not only boosts efficiency but also ensures compliance with rigorous standards, ultimately delivering safer products to end-users. If challenges persist, leaning on expert support makes all the difference. Stay proactive, and your blister packaging operations will run smoother than ever.

FAQs

What causes frequent jams in blister forming equipment?

Often, it's due to material misalignment or debris - regular cleaning and proper tension adjustments usually resolve it.

How do I know if my blister sealing machine needs calibration?

Look for inconsistent seals or error codes; annual professional checks are ideal for cGMP compliance.

Can I handle electrical issues myself?

Basic checks like sensor cleaning are fine, but complex wiring demands certified technicians to avoid risks.

What's the best way to extend machine lifespan?

Implement preventive maintenance, including routine inspections and staff training on blister pack machinery.

Why Choose Haichina for Your Pharmaceutical Blistering Machine Solutions?

Drawing from this comprehensive troubleshooting guide, Haichina stands out as a premier factory and manufacturer of pharmaceutical blistering machines, offering robust, CE-certified equipment tailored for global markets. With roots since 2004, we specialize in automatic packaging lines that enhance efficiency in pharma blister packaging. Our innovative designs meet cGMP standards, ensuring reliability and minimal downtime. As a trusted supplier to over 50 countries, we provide timely after-sales support and custom solutions. Elevate your operations with our quality blister forming machines - contact us at [email protected] to discuss your needs and secure competitive advantages today.

References

"Pharmaceutical Packaging Technology" by Dean and Evans, published by Taylor & Francis in 2000.

"Handbook of Pharmaceutical Manufacturing Formulations" by Sarfaraz K. Niazi, published by CRC Press in 2009.

"Packaging of Pharmaceuticals and Healthcare Products" by Frank A. Paine and H. Lockhart, published by Blackie Academic & Professional in 1996.

"Blister Packaging: Materials, Processes, and Equipment" by Edward J. Bauer, published in the Journal of Packaging Technology in 2015.

"Good Manufacturing Practices for Pharmaceuticals" by Sidney H. Willig, published by Marcel Dekker in 2001.

"Automation in Pharmaceutical Packaging" by Mike Wilson, featured in Pharmaceutical Engineering Magazine in 2018.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?