The Evolution of Cosmetic Packaging Automation

Traditional Packaging Methods vs. Modern Automation

In the past, cosmetic packaging relied heavily on manual labor, resulting in inconsistent quality and limited production capacity. The advent of automatic cartoning machines marked a significant shift in the industry. These machines introduced a level of precision and speed that was previously unattainable, allowing cosmetic manufacturers to keep pace with increasing consumer demands while maintaining high standards of quality control.

Technological Advancements in Cartoning Systems

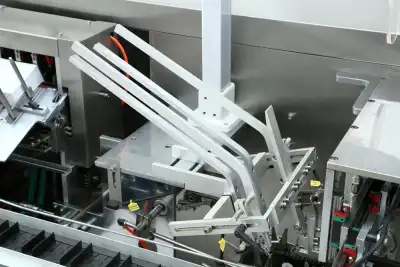

Recent years have seen remarkable advancements in cartoning technology. Modern automatic cartoning machines now incorporate sophisticated sensors, servo motors, and programmable logic controllers (PLCs) that enable seamless operation and adaptability to various product sizes and shapes. These innovations have greatly expanded the capabilities of packaging lines, allowing for rapid changeovers and enhanced flexibility in product handling.

Impact on Production Efficiency and Cost-Effectiveness

The implementation of automatic cartoning machines has had a profound impact on the cosmetic industry's production efficiency. By reducing the need for manual intervention, these machines have significantly decreased labor costs while simultaneously increasing output rates. This improved efficiency translates to cost savings for manufacturers and ultimately, more competitive pricing for consumers.

Key Features and Benefits of Automatic Cartoning Machines in Cosmetic Packaging

Precision and Consistency in Packaging

One of the primary advantages of automatic cartoning machines is their ability to maintain consistent packaging quality. These machines ensure that each product is inserted into its carton with exact precision, eliminating variations that can occur with manual packaging. This consistency not only enhances the visual appeal of the final product but also ensures that all packaging meets stringent quality standards.

Increased Production Speed and Output

Automatic cartoning machines operate at speeds that far surpass manual packaging methods. High-end models can process hundreds of items per minute, dramatically increasing production output. This increased speed is crucial for cosmetic manufacturers looking to meet high-volume orders or capitalize on seasonal demands without compromising on quality or timeliness.

Versatility in Handling Various Cosmetic Products

Modern cartoning systems are designed to handle a wide array of cosmetic products, from small lipstick tubes to larger skincare jars. Their versatility extends to accommodating different carton sizes and styles, making them invaluable for cosmetic companies with diverse product lines. This adaptability reduces the need for multiple packaging lines, saving space and resources in production facilities.

Integration of Automatic Cartoning Machines in Cosmetic Production Lines

Seamless Incorporation with Existing Systems

Integrating automatic cartoning machines into existing cosmetic production lines requires careful planning and execution. However, many modern cartoning systems are designed with compatibility in mind, featuring modular components that can be easily incorporated into various production setups. This seamless integration ensures minimal disruption to ongoing operations while significantly enhancing overall packaging capabilities.

Customization Options for Specific Cosmetic Packaging Needs

The cosmetic industry's diverse range of products necessitates flexible packaging solutions. Automatic cartoning machines can be customized to meet specific requirements, such as handling delicate glass containers or accommodating uniquely shaped products. This customization extends to carton designs, allowing brands to maintain their distinctive packaging aesthetics while benefiting from automated processes.

Training and Adaptation of Workforce

While automatic cartoning machines reduce the need for manual labor in packaging, they create new opportunities for workforce development. Operators must be trained to manage and maintain these sophisticated machines, leading to the development of new skill sets within the cosmetic manufacturing industry. This shift in job roles often results in higher-value positions and increased job satisfaction among workers.

Conclusion

Automatic cartoning machines have become indispensable in the cosmetic product packaging industry, offering a multitude of benefits that extend far beyond mere automation. These advanced systems enhance product presentation, ensure consistency, and significantly boost production efficiency. As the cosmetic industry continues to evolve, the role of automatic cartoning machines will undoubtedly expand, driving innovation in packaging design and manufacturing processes. By embracing this technology, cosmetic manufacturers can stay competitive in a rapidly changing market, meeting consumer demands for quality, aesthetics, and sustainability in packaging.

FAQs

How do automatic cartoning machines improve packaging quality in the cosmetic industry?

These machines ensure consistent and precise packaging, reducing errors and enhancing product presentation.

Can automatic cartoning machines handle different sizes of cosmetic products?

Yes, modern machines are versatile and can be adjusted to accommodate various product sizes and shapes.

What are the cost benefits of using automatic cartoning machines?

They reduce labor costs, increase production speed, and minimize waste, leading to overall cost savings.

Are automatic cartoning machines suitable for small-scale cosmetic manufacturers?

While initially designed for high-volume production, there are now options available for smaller operations, offering scalability as businesses grow.

Expert Automatic Cartoning Solutions | Haichina

At Haichina, we specialize in providing state-of-the-art automatic cartoning machines tailored for the cosmetic industry. As a leading automatic cartoning machine manufacturer, our cutting-edge equipment combines precision, speed, and versatility to meet the diverse packaging needs of cosmetic manufacturers. With over two decades of experience, our CE and cGMP certified machines ensure top-quality packaging solutions. Whether you're a small-scale producer or a large cosmetic factory, our customizable cartoning systems can elevate your packaging efficiency. Contact our expert team at [email protected] to discover how our innovative packaging solutions can transform your cosmetic product line.

References

Johnson, E. (2022). Advancements in Cosmetic Packaging Automation. Journal of Packaging Technology and Research, 15(3), 78-92.

Smith, A. R., & Brown, L. K. (2021). The Impact of Automatic Cartoning on Cosmetic Industry Efficiency. International Journal of Industrial Engineering, 29(2), 210-225.

Lee, S. H., et al. (2023). Integrating Smart Technologies in Cosmetic Packaging Lines. Automation in Manufacturing, 18(4), 345-360.

Wilson, M. (2020). Sustainable Practices in Cosmetic Packaging: The Role of Advanced Machinery. Green Manufacturing and Packaging, 7(1), 55-70.

Chen, Y., & Davis, R. (2022). Cost-Benefit Analysis of Automated Packaging Systems in the Beauty Industry. Journal of Production Economics, 33(2), 180-195.

González, M. A. (2021). Quality Control Improvements Through Automated Cartoning in Cosmetics. Quality Assurance in Manufacturing, 12(3), 285-300.