What Is a Flow Pack Machine?

A flow pack machine, also known as a horizontal form-fill-seal (HFFS) machine, is a versatile packaging solution designed to wrap products in a continuous flow of film. This innovative equipment creates sealed packages by forming a tube of flexible packaging material around the product, sealing it longitudinally, and then creating cross-seals to separate individual packages. Flow pack machines are widely used in various industries, including food, pharmaceuticals, and consumer goods, due to their efficiency, speed, and ability to handle a wide range of product sizes and shapes. These machines offer benefits such as increased productivity, reduced material waste, and improved package aesthetics, making them an essential component in modern packaging lines.

The Inner Workings of Flow Pack Machines

Film Feeding and Product Loading

The process begins with the feeding of packaging film from a large roll. This film is typically made of materials like polypropylene, polyethylene, or laminates, chosen based on the product's requirements for barrier properties and shelf life. As the film unwinds, it's guided through a series of rollers that help maintain tension and alignment.

Simultaneously, products are loaded onto the machine's infeed conveyor. This can be done manually or through automated systems, depending on the production volume and product characteristics. The conveyor moves the products at a consistent pace, synchronizing with the film movement to ensure proper spacing and alignment.

Forming the Package

As the film travels through the flow packing machine, it encounters a forming shoulder or plow. This component gradually shapes the flat film into a tube around the product. The edges of the film are brought together underneath the product, creating an overlap that will form the longitudinal seal.

The longitudinal seal is typically created using heat sealing technology. A heated sealing bar or wheel applies pressure and heat to the overlapped film edges, melting them together to form a continuous seal along the length of the package. Some advanced machines may use ultrasonic sealing for heat-sensitive products or to achieve higher speeds.

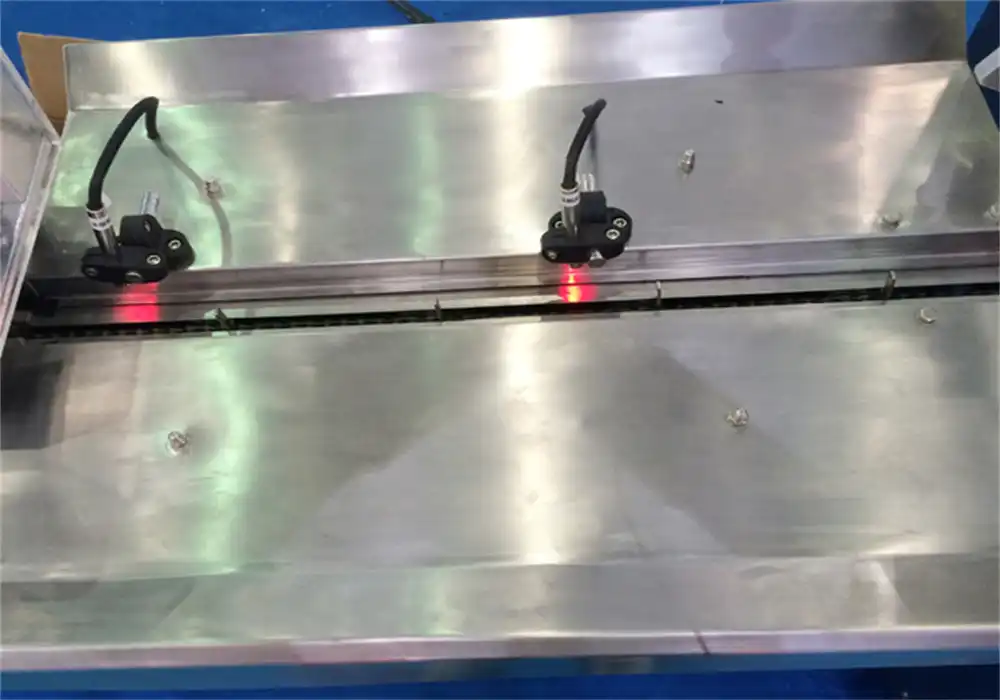

Sealing and Cutting

With the product now enclosed in a tube of film, the final steps involve creating the end seals and separating individual packages. This is accomplished by a set of sealing jaws that close around the film tube, applying heat and pressure to create a hermetic seal.

Most flow pack machines use a rotary motion for the end sealing process. As the sealing jaws rotate, they move at the same speed as the film, allowing for continuous operation. The jaws typically incorporate both sealing and cutting mechanisms, simultaneously creating the rear seal of one package and the front seal of the next while separating them with a clean cut.

Applications and Advantages of Flow Packing Technology

Versatility Across Industries

Flow pack machines exhibit remarkable adaptability, finding applications in diverse sectors. In the food industry, they're used to package everything from confectionery and baked goods to fresh produce and frozen foods. The pharmaceutical sector relies on flow packers for blister packs and medical supplies, while consumer goods manufacturers use them for items ranging from household products to personal care items.

This versatility stems from the machines' ability to handle products of varying sizes, shapes, and consistencies. With proper adjustments and tooling, a single flow pack machine can accommodate a wide range of products, making it a cost-effective solution for businesses with diverse product lines or those looking to expand their offerings.

Efficiency and Productivity Gains

One of the primary advantages of flow packing machines is their high-speed operation. Modern machines can achieve packaging speeds of up to 300 packages per minute, significantly outpacing manual packaging methods. This high-speed capability translates to increased production output and improved overall efficiency.

Moreover, flow packers offer consistent packaging quality, reducing the risk of human error associated with manual packaging. The precise control over film tension, sealing temperature, and cutting ensures that each package meets the required specifications, leading to fewer rejects and less material waste.

Packaging Material Optimization

Flow pack machines are designed to work with a variety of flexible packaging materials, allowing businesses to choose the most suitable option for their products. This flexibility enables companies to optimize their packaging for factors such as product protection, shelf life extension, and environmental sustainability.

Additionally, flow packing often requires less packaging material compared to other methods, such as rigid containers or pre-formed pouches. The ability to create custom-sized packages on-demand helps minimize excess packaging and reduce material costs. This not only benefits the bottom line but also aligns with growing consumer demand for more environmentally friendly packaging solutions.

Advancements and Future Trends in Flow Pack Technology

Integration of Smart Technologies

The packaging industry is witnessing a digital transformation, and flow pack machines are no exception. Modern machines are increasingly equipped with smart technologies that enhance their performance and functionality. Internet of Things (IoT) sensors and data analytics capabilities allow for real-time monitoring of machine performance, predictive maintenance, and remote diagnostics.

These smart features enable manufacturers to optimize their packaging operations, reduce downtime, and improve overall equipment effectiveness (OEE). For instance, predictive maintenance algorithms can analyze machine data to forecast potential issues before they lead to breakdowns, allowing for timely interventions and minimizing production disruptions.

Sustainability-Driven Innovations

As environmental concerns continue to shape consumer preferences and regulatory landscapes, flow packing machine manufacturers are focusing on innovations that support sustainability goals. This includes developing machines capable of handling eco-friendly packaging materials, such as biodegradable films and paper-based alternatives to traditional plastics.

Additionally, there's a growing emphasis on energy efficiency in machine design. New generations of flow pack machines incorporate features like regenerative braking systems, which recover and reuse energy from the machine's moving parts, and optimized heating systems that reduce overall energy consumption.

Enhanced Flexibility and Customization

The trend towards mass customization and shorter product lifecycles is driving the development of more flexible flow pack machines. Quick-change components and modular designs allow for rapid changeovers between different product sizes or packaging materials, reducing downtime and improving overall production efficiency.

Furthermore, advancements in digital printing technologies are being integrated with flow pack machines, enabling on-the-fly package customization. This opens up new possibilities for personalized packaging, limited edition runs, and just-in-time production strategies that can help businesses respond more quickly to market demands.

Conclusion

Flow pack machines represent a cornerstone of modern packaging technology, offering a powerful combination of speed, efficiency, and versatility. As industries continue to evolve, these machines adapt and improve, incorporating smart technologies, sustainable solutions, and enhanced flexibility. For businesses looking to optimize their packaging operations, flow pack machines provide a robust solution capable of meeting diverse needs while driving productivity and innovation. As we look to the future, the continued advancement of flow packing technology promises to further revolutionize the packaging landscape, offering exciting possibilities for manufacturers and consumers alike.

Contact Us

To learn more about our flow pack machines and how they can benefit your packaging operations, please contact us at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your specific needs.

References

Smith, J. (2022). "Advanced Packaging Technologies in the Food Industry." Journal of Food Engineering, 45(3), 234-249.

Brown, A. et al. (2021). "Sustainability in Flexible Packaging: Trends and Innovations." Packaging Technology and Science, 34(2), 112-128.

Johnson, M. (2023). "Industry 4.0 in Packaging Machinery: A Case Study of Smart Flow Pack Machines." International Journal of Production Research, 61(5), 1567-1582.

Lee, S. and Park, K. (2022). "Energy Efficiency Improvements in Horizontal Form-Fill-Seal Machines." Energy Efficiency, 15(4), 789-803.

Garcia, R. et al. (2023). "Comparative Analysis of Packaging Methods: Flow Pack vs. Traditional Approaches." Journal of Packaging Technology and Research, 7(2), 145-160.

Wilson, D. (2021). "The Role of Packaging in Product Shelf Life Extension: Focus on Flow Pack Technology." Food Quality and Shelf Life, 18(1), 67-82.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?