What Is a Flow Packing Machine Used For?

A flow packing machine is a pivotal piece of equipment designed to streamline the packaging process across various industries. This ingenious apparatus encases products in a protective film, ensuring they remain fresh, secure, and visually appealing during transit and storage. Primarily utilized in sectors such as foodstuff, pharmaceuticals, cosmetics, and commodities, it excels at wrapping items of diverse shapes and sizes - ranging from bakery goods to medical supplies. By automating the wrapping procedure, this machinery enhances efficiency, reduces labor costs, and maintains stringent hygiene standards, making it indispensable for manufacturers aiming to scale production while adhering to global quality benchmarks like CE and cGMP.

Understanding the Mechanics of Flow Packing Machines

How the Technology Operates?

Delving into the intricacies of a flow packing machine reveals a sophisticated orchestration of components working in unison. At its core, the equipment employs a continuous roll of film, which is deftly shaped into a tube around the product. As the item advances along a conveyor, the film is sealed longitudinally, creating a snug enclosure. Subsequently, transverse seals are applied at both ends, encapsulating the product securely. This seamless operation, often referred to as horizontal form-fill-seal, is lauded for its celerity and precision, accommodating high-volume production without compromising on quality. The adaptability of this technology to various film types, including biodegradable options, further underscores its versatility.

Key Components That Drive Efficiency

The efficacy of flow packing machine hinges on several integral elements. The infeed conveyor, which transports products into the system, ensures a steady flow, while the film unwinding mechanism guarantees a consistent supply of wrapping material. Temperature-controlled sealing jaws are paramount, as they facilitate robust seals that safeguard product integrity. Additionally, advanced models incorporate sensors and programmable logic controllers, enabling meticulous adjustments to accommodate diverse product dimensions and packaging requisites. This synergy of components not only bolsters operational efficiency but also minimizes waste, aligning with sustainable manufacturing practices - a priority for global enterprises.

Customization Options for Diverse Industries

One of the standout attributes of flow packing equipment is its capacity for customization. Manufacturers can tailor these machines to meet the idiosyncratic demands of their sector. In the pharmaceutical realm, for instance, the machinery can be equipped with anti-contamination features to comply with stringent regulatory standards. Conversely, in the foodstuff sector, options like gas flushing can be integrated to extend shelf life by modifying the internal atmosphere of the package. Such bespoke modifications ensure that whether the task involves wrapping confectionery or medical devices, the equipment delivers unparalleled performance, cementing its status as a linchpin in modern packaging solutions.

Applications of Flow Packing Machines Across Industries

Enhancing Foodstuff Packaging

In the realm of food production, flow packing machines are nothing short of revolutionary. These apparatuses excel at encasing perishable goods - think bakery items, snacks, and fresh produce - in airtight packaging that preserves freshness and augments shelf life. The ability to handle irregular shapes, such as loaves of bread or clusters of fruit, without compromising on speed is a testament to their ingenuity. Moreover, the integration of features like modified atmosphere packaging ensures that products remain untainted by external elements, a crucial factor for manufacturers aiming to meet global food safety standards while captivating consumers with pristine presentation.

Streamlining Pharmaceutical and Cosmetic Packaging

The pharmaceutical and cosmetic industries demand precision and hygiene, areas where flow packing machine shines. For pharmaceuticals, these machines are adept at wrapping blister packs, syringes, and other medical paraphernalia, ensuring they remain sterile and tamper-proof. In cosmetics, the equipment is employed to package items like lipsticks, creams, and compacts, offering protection against environmental degradation while enhancing visual appeal. The adherence to cGMP guidelines, coupled with the ability to incorporate serialization for traceability, positions this machinery as an invaluable asset for manufacturers navigating the labyrinthine regulations of these sectors.

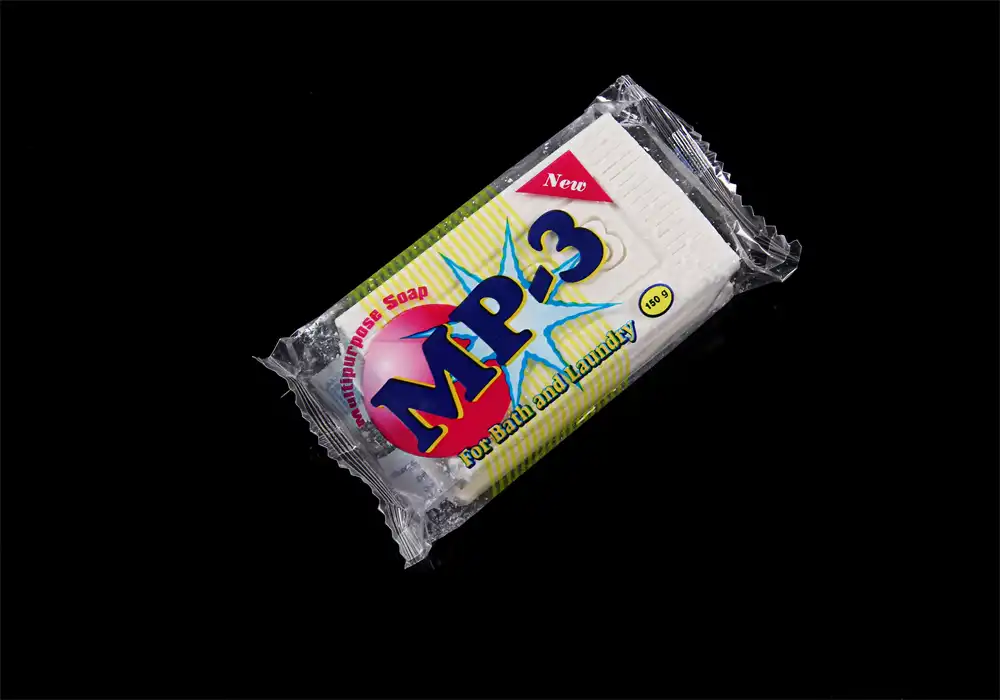

Versatility in Commodity Packaging

Beyond specialized industries, flow packing machines demonstrate remarkable versatility in handling everyday commodities. From household goods like sponges and batteries to hardware items such as screws and fittings, these machines provide a robust packaging solution that safeguards products during transit. The ability to wrap multiple items in a single package - known as multipacking - further enhances their utility, allowing manufacturers to offer bundled products that appeal to cost-conscious consumers. This adaptability not only streamlines logistics but also fortifies brand integrity by ensuring products reach end-users in impeccable condition.

Benefits of Integrating Flow Packing Machines into Your Production Line

Boosting Operational Efficiency

The incorporation of flow packing machinery into a production line heralds a paradigm shift in operational efficiency. By automating the packaging process, these machines drastically reduce the reliance on manual labor, thereby curtailing costs and mitigating human error. The high-speed capabilities - often processing hundreds of units per minute - enable manufacturers to meet burgeoning demand without sacrificing quality. Additionally, the precision of the sealing process minimizes material wastage, aligning with lean manufacturing principles. For global enterprises, this efficiency translates into a competitive edge, allowing them to fulfill large-scale orders with alacrity.

Ensuring Product Safety and Compliance

In an era where regulatory compliance is non-negotiable, flow packing machines offer a bulwark against non-conformance. The hermetic seals produced by these machines protect products from contaminants, moisture, and physical damage, ensuring they meet stringent quality standards. For industries like pharmaceuticals, where adherence to CE and cGMP certifications is paramount, the machinery's ability to integrate validation protocols is invaluable. Furthermore, the tamper-evident packaging enhances consumer trust, a critical factor in sectors where product integrity is synonymous with brand reputation. This confluence of safety and compliance fortifies a manufacturer's standing in the global marketplace.

Elevating Brand Appeal Through Packaging

Packaging is not merely a functional necessity; it is a potent marketing tool, and flow packing machines excel at enhancing brand allure. The machinery's ability to utilize transparent or printed films allows manufacturers to showcase their products while conveying essential information, such as branding and nutritional data. The impeccable finish of the packaging - free from wrinkles or imperfections - creates a professional impression that resonates with discerning consumers. Moreover, the option to use eco-friendly materials caters to the growing demand for sustainable practices, further burnishing a brand's reputation as a responsible entity in the eyes of environmentally conscious patrons.

Conclusion

Flow packing machines are transformative assets for manufacturers across diverse sectors, offering a blend of efficiency, safety, and aesthetic appeal. By automating the packaging process, they empower businesses to scale production, adhere to rigorous standards, and captivate consumers with impeccable presentation. Whether you're in foodstuff, pharmaceuticals, cosmetics, or commodities, integrating this technology into your production line can redefine your operational paradigm, ensuring you remain competitive in a global arena.

Contact Us

Ready to elevate your packaging solutions with cutting-edge flow packing machine? Contact Zhejiang Haizhong Machinery Co., Ltd. at [email protected] to explore how our innovative equipment can meet your needs.

References

Smith, J. (2022). Modern Packaging Technologies: Innovations in Efficiency and Sustainability. Industrial Press.

Brown, L. (2021). Pharmaceutical Packaging: Compliance and Quality Assurance. Regulatory Publications.

Patel, R. (2023). Food Packaging Solutions: Extending Shelf Life Through Technology. Food Science Journals.

Thompson, E. (2020). Automation in Manufacturing: The Role of Packaging Machinery. Engineering Insights.

Garcia, M. (2022). Sustainable Packaging Practices in Global Markets. Environmental Technology Review.

Lee, K. (2021). Cosmetic Packaging: Balancing Aesthetics and Functionality. Beauty Industry Reports.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?