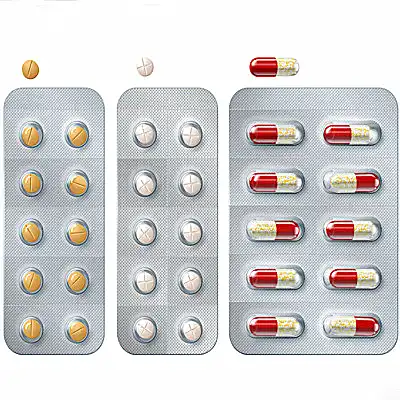

The Role of Different Plastics in Blister Packaging

Polyvinyl Chloride (PVC): The Versatile Option

Polyvinyl Chloride, commonly known as PVC, is one of the most versatile plastics used in blister packaging. Its popularity stems from its excellent formability, which allows it to be easily molded into various shapes and sizes. PVC also provides good barrier properties against moisture and gases, making it ideal for protecting sensitive products. However, environmental concerns have led some manufacturers to seek alternatives, as PVC is not easily recyclable and can release harmful chemicals when incinerated.

Polyethylene Terephthalate (PET): The Clear Choice

PET is another widely used plastic in blister packaging, particularly favored for its exceptional clarity and transparency. This makes it an excellent choice for products where visual appeal is crucial, such as cosmetics or electronics. PET also offers good barrier properties and is more environmentally friendly than PVC, as it is easily recyclable. Its strength and durability make it suitable for use in blister packaging machines, ensuring efficient production processes.

Polypropylene (PP): The Moisture-Resistant Alternative

Polypropylene is gaining popularity in blister packaging due to its excellent moisture barrier properties. This makes it particularly suitable for products that are sensitive to humidity. PP is also known for its high heat resistance, making it a good choice for products that may be exposed to elevated temperatures during storage or transportation. Additionally, PP is considered more environmentally friendly than PVC, as it can be recycled more easily.

Factors Influencing the Choice of Plastic in Blister Packaging

Product Requirements and Compatibility

The choice of plastic for blister packaging largely depends on the specific requirements of the product being packaged. Factors such as moisture sensitivity, light exposure, and chemical compatibility play a crucial role in material selection. For instance, pharmaceuticals may require materials with high barrier properties to protect against moisture and oxygen, while food products might need materials that can withstand temperature fluctuations. Manufacturers must carefully consider these factors when choosing the appropriate plastic for their blister packaging machine.

Environmental Considerations and Sustainability

With increasing focus on environmental sustainability, the choice of plastic for blister packaging is also influenced by eco-friendly considerations. Materials that are easily recyclable or biodegradable are gaining favor among manufacturers and consumers alike. This has led to increased use of PET and PP, which are more readily recyclable compared to PVC. Some companies are also exploring bio-based plastics as alternatives, aiming to reduce their carbon footprint and appeal to environmentally conscious consumers.

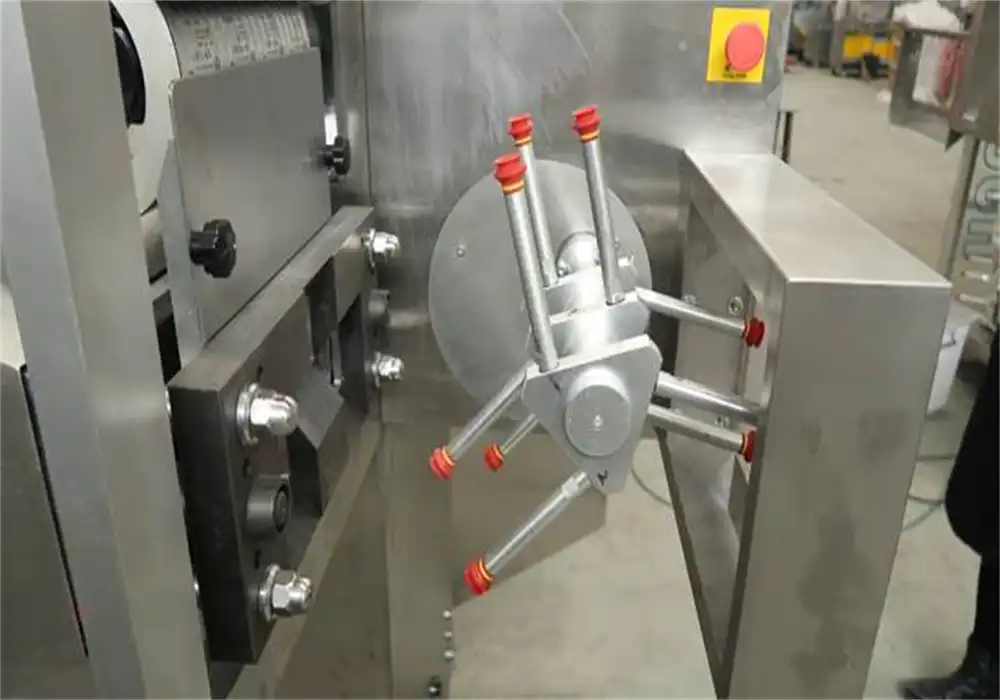

Cost-Effectiveness and Production Efficiency

The cost of materials and their compatibility with existing blister packaging machines are significant factors in the selection process. While some materials may offer superior properties, they might be more expensive or require specialized equipment for processing. Manufacturers must balance the cost of materials with the overall efficiency of their packaging process. This includes considering factors such as material formability, sealing properties, and compatibility with high-speed blister packaging machines to ensure optimal production efficiency.

Innovations and Future Trends in Blister Packaging Materials

Smart and Active Packaging Materials

The future of blister packaging is seeing a shift towards smart and active materials. These innovative plastics can incorporate features such as temperature indicators, freshness sensors, or even antimicrobial properties. Such advancements are particularly valuable in the pharmaceutical and food industries, where maintaining product integrity is crucial. These smart materials can be seamlessly integrated into existing blister packaging machine processes, offering enhanced functionality without significant changes to production methods.

Biodegradable and Compostable Alternatives

As environmental concerns continue to grow, there's an increasing focus on developing biodegradable and compostable materials for blister packaging. These materials aim to provide the same protective properties as traditional plastics while reducing environmental impact. Innovations in this area include plastics derived from plant-based sources or materials designed to break down more easily in natural environments. While these alternatives are promising, challenges remain in matching the performance and cost-effectiveness of traditional plastics in high-speed blister packaging machine applications.

Nanotechnology in Packaging Materials

Nanotechnology is opening new frontiers in blister packaging materials. By manipulating materials at the nanoscale, researchers are developing plastics with enhanced barrier properties, improved strength, and even self-healing capabilities. These advancements could lead to thinner, lighter, and more effective packaging materials. For manufacturers using blister packaging machines, this could mean improved efficiency, reduced material costs, and enhanced product protection. However, the integration of nanotechnology in packaging materials is still in its early stages and requires further research and development.

Conclusion

The choice of plastic for blister packaging is a crucial decision that impacts product protection, consumer satisfaction, and environmental sustainability. While PVC, PET, and PP remain the most common materials, ongoing innovations are expanding the options available to manufacturers. As the industry evolves, the focus is shifting towards materials that not only perform well in blister packaging machines but also address environmental concerns and offer enhanced functionalities. By staying informed about these developments, manufacturers can make informed decisions that balance product requirements, production efficiency, and sustainability goals.

Contact Us

For more information about our blister packaging machines and how we can help you choose the right packaging solutions for your products, please contact us at [email protected]. Our team of experts is ready to assist you in optimizing your packaging process with the latest technologies and materials.