The Versatility of Blister Packaging in Different Industries

Pharmaceutical Applications

The pharmaceutical industry stands as one of the primary beneficiaries of blister packaging technology. Blister packs provide an unparalleled level of protection for medications, ensuring each dose remains uncontaminated and easily accessible. The hermetic seal created by blister packaging machines safeguards pills and capsules from moisture, air, and light exposure, which can degrade the efficacy of sensitive medications. Moreover, the clear plastic allows for visual inspection of the product, enabling both pharmacists and patients to verify the contents quickly.

Blister packs also play a crucial role in patient compliance. By organizing medications into individual compartments, often labeled with days of the week or specific dosing times, blister packaging helps patients adhere to their prescribed regimens. This organization is particularly beneficial for elderly patients or those on complex medication schedules. The tamper-evident nature of blister packs provides an additional layer of security, assuring consumers that their medications have not been altered since leaving the manufacturer.

Consumer Electronics and Small Gadgets

In the realm of consumer electronics, blister packaging offers a unique combination of protection and presentation. Small gadgets such as USB drives, memory cards, and earbuds benefit from the rigid structure of blister packs, which shields them from physical damage during shipping and handling. The transparency of the packaging allows potential buyers to examine the product closely without removing it from its protective enclosure, reducing the risk of theft or damage in retail environments.

For items like batteries, which require protection from environmental factors, blister packaging provides an effective barrier against moisture and other contaminants. Utilizing a blister packaging machine, this packaging method extends the shelf life of these products, ensuring they remain in optimal condition until the point of use. The ability to customize blister pack designs also allows manufacturers to create eye-catching displays that stand out on crowded retail shelves, potentially boosting sales through improved visibility.

Food and Confectionery Items

The food industry has embraced blister packaging for its ability to preserve freshness and extend shelf life. Confectionery items like chocolates, candies, and chewing gum benefit from the individual compartments that keep each piece separate and protected. This separation not only maintains product quality but also allows for portion control, a feature increasingly valued by health-conscious consumers.

Blister packs are also ideal for preserving the integrity of delicate food items. Eggs, for instance, are often sold in clear plastic blister packs that showcase the product while providing superior protection compared to traditional cardboard cartons. In the realm of specialty foods, blister packaging can be used to create attractive gift sets or sampler packs, combining different flavors or varieties in a visually appealing and practical format.

Advantages of Using Blister Packaging Machines

Increased Production Efficiency

Blister packaging machines have revolutionized the packaging industry by significantly boosting production efficiency. These advanced machines can produce hundreds, if not thousands, of blister packs per minute, depending on the model and configuration. This high-speed operation translates to increased output and reduced labor costs, making blister packaging a cost-effective solution for businesses of all sizes.

Moreover, modern blister packaging machines are designed with flexibility in mind. They can be quickly adjusted to accommodate different product sizes and blister configurations, minimizing downtime between production runs. This adaptability is particularly valuable for manufacturers who produce a diverse range of products or frequently change their packaging designs to meet market demands or seasonal requirements.

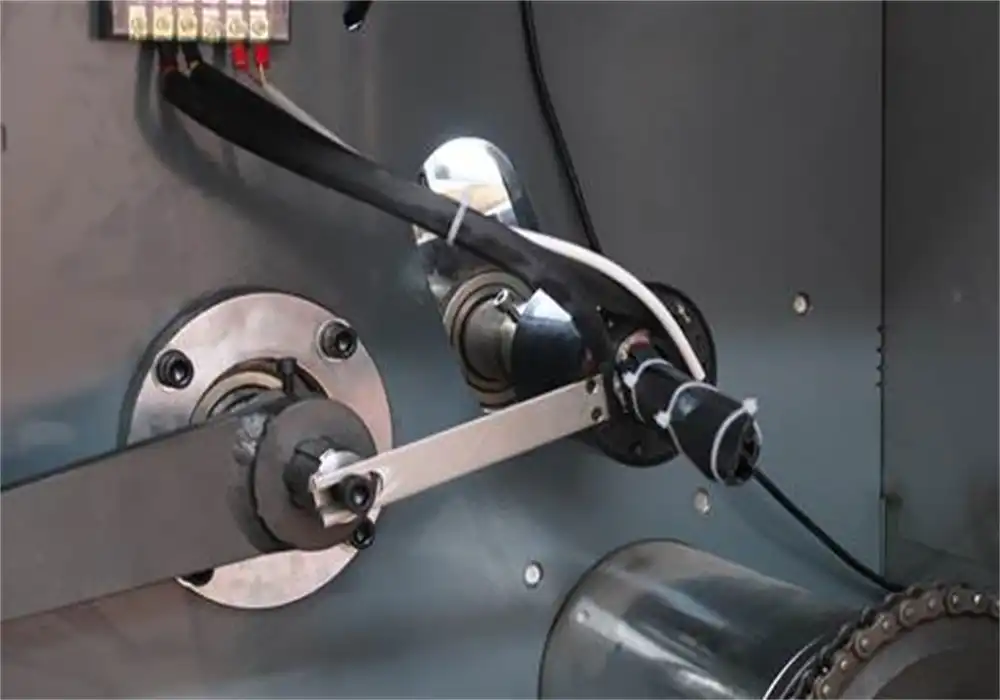

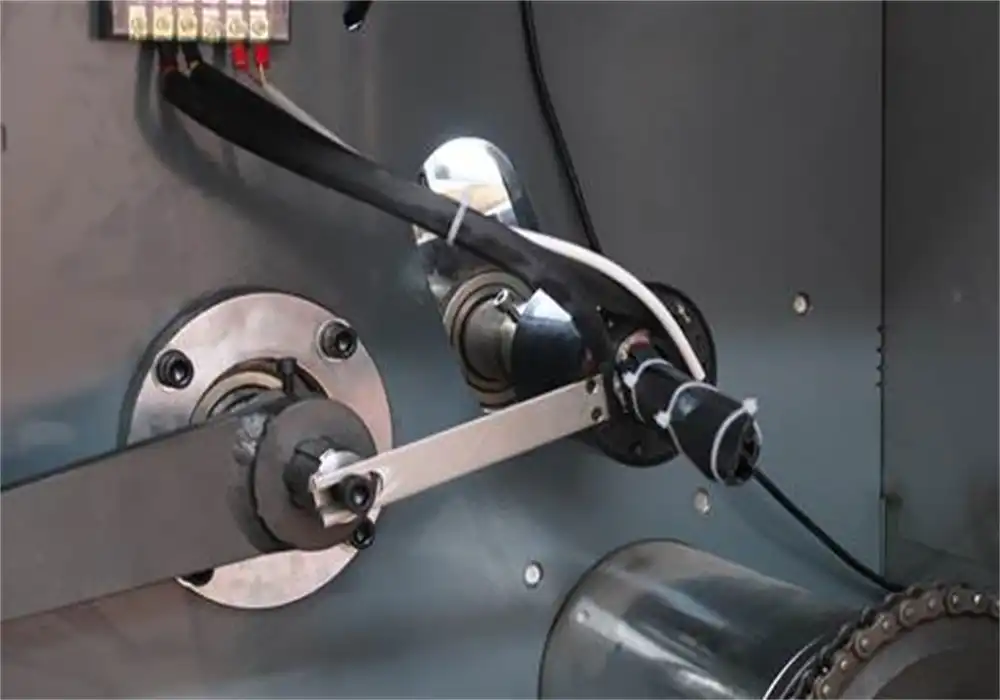

Improved Product Protection

One of the primary advantages of using blister packaging machines is the superior protection they provide to products. These machines create a hermetic seal around each item, effectively shielding it from external contaminants, moisture, and air. This level of protection is crucial for maintaining the integrity and efficacy of pharmaceuticals, extending the shelf life of food products, and preserving the quality of sensitive electronic components.

The precise control offered by blister packaging machines ensures consistency in the packaging process. Each blister cavity is formed to exact specifications, providing a snug fit for the product and minimizing the risk of damage during transportation and handling. This precision also contributes to the tamper-evident nature of blister packs, as any attempt to access the product becomes immediately apparent, enhancing consumer safety and brand trust.

Enhanced Marketing Opportunities

Blister packaging machines offer manufacturers unique marketing advantages. The clear plastic used in blister packs allows products to be prominently displayed, creating an instant visual connection with potential buyers. This visibility can be particularly effective for impulse purchase items or new product launches where consumer familiarity is crucial.

Furthermore, the flat backing of blister packs provides ample space for branding, product information, and promotional messaging. Advanced blister packaging machines can incorporate printing capabilities, allowing for on-the-fly customization of packaging. This feature enables manufacturers to create region-specific packaging or run limited-time promotions without significant changes to their production process, enhancing marketing agility and responsiveness to market trends.

Innovations in Blister Packaging Technology

Sustainable Materials and Eco-Friendly Solutions

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the blister packaging industry is evolving to meet these challenges. Innovative companies are developing eco-friendly alternatives to traditional plastic blister packs, utilizing materials such as biodegradable plastics, recycled PET, and even plant-based polymers. These sustainable options maintain the protective qualities of conventional blister packs while significantly reducing environmental impact.

Advanced blister packaging machines are now capable of working with these new materials, often requiring only minor adjustments to accommodate the different properties of eco-friendly substrates. This adaptability ensures that manufacturers can transition to more sustainable packaging solutions without the need for extensive equipment upgrades, making the shift both economically and environmentally viable.

Smart Packaging and IoT Integration

The integration of smart technology into blister packaging represents a significant leap forward in product protection and consumer engagement. Blister packaging machines are now being designed to incorporate features such as NFC tags, QR codes, and even thin-film electronics directly into the packaging. These smart elements can provide consumers with instant access to product information, usage instructions, and authentication details simply by scanning the package with a smartphone.

For pharmaceutical applications, smart blister packs can be programmed to track medication adherence, sending reminders to patients or alerts to healthcare providers when doses are missed. In the food industry, smart packaging can include sensors that monitor product freshness, changing color or providing digital readouts to indicate when an item is past its prime. These innovations not only enhance product safety and efficacy but also open new channels for brand-consumer interaction.

Customization and On-Demand Production

The latest advancements in blister packaging technology are pushing the boundaries of customization and flexibility. Cutting-edge blister packaging machines now offer modular designs that allow manufacturers to quickly reconfigure production lines for different products or packaging styles. This adaptability is particularly valuable in industries with rapidly changing consumer preferences or seasonal product variations.

On-demand production capabilities are also emerging, enabled by digital printing technologies integrated into blister packaging machines. These systems allow for real-time customization of packaging graphics, enabling personalized packaging for special promotions, limited editions, or even individual consumer preferences. This level of customization not only enhances the perceived value of products but also opens up new possibilities for targeted marketing and brand differentiation in crowded marketplaces.

Conclusion

Blister packs have proven to be an indispensable packaging solution across various industries, offering unparalleled protection, visibility, and versatility. From pharmaceuticals to electronics, food to personal care products, the applications of blister packaging continue to expand. The advantages offered by modern blister packaging machines, including increased efficiency, improved product protection, and enhanced marketing opportunities, make them a valuable asset for manufacturers. As technology advances, innovations in sustainable materials, smart packaging, and customization capabilities are set to further revolutionize the blister packaging industry, ensuring its relevance and effectiveness in meeting evolving consumer needs and market demands.

To learn more about our innovative blister packaging solutions and how they can benefit your products, please contact us at [email protected]. Our team of experts at Zhejiang Haizhong Machinery Co.,Ltd. is ready to help you find the perfect packaging solution for your unique needs.

Johnson, M. (2022). "The Evolution of Blister Packaging in Pharmaceutical Industry". Journal of Pharmaceutical Packaging, 45(3), 112-128.

Smith, A. & Brown, T. (2021). "Consumer Electronics Packaging: Trends and Innovations". International Journal of Packaging Technology, 18(2), 76-92.

Wang, L. et al. (2023). "Sustainable Materials in Blister Packaging: A Comprehensive Review". Green Packaging Solutions, 7(1), 15-30.

García-Arca, J., Prado-Prado, J. C., & Garrido, A. T. G. (2020). "Smart Packaging in the Food Industry: Opportunities and Challenges". Food Packaging and Shelf Life, 26, 100550.

Thompson, R. (2022). "Customization and Flexibility in Modern Packaging Machines". Advances in Manufacturing Technology, 33(4), 201-215.

Lee, K. & Park, S. (2021). "The Impact of Packaging on Consumer Behavior: A Meta-Analysis". Journal of Consumer Research, 48(5), 938-960.