Understanding Automatic Blister Packing Machines

The Mechanics of Blister Packaging

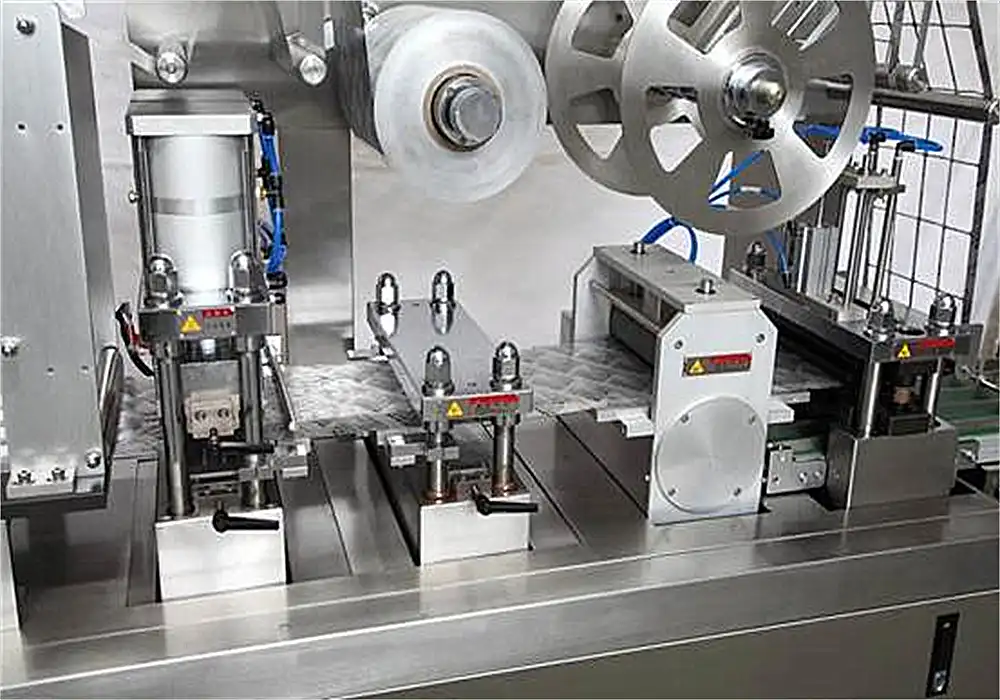

Automatic blister packing machines are sophisticated pieces of equipment designed to package individual units of products, typically pharmaceuticals, in sealed plastic cavities backed by a layer of aluminum foil or paper. The process begins with thermoforming, where a sheet of plastic is heated and molded into cavity shapes. Products are then precisely placed into these cavities before the backing material is heat-sealed to create a secure package.

Advantages of Blister Packaging

Blister packaging offers numerous benefits, making it a preferred choice in many industries. It provides excellent product visibility, allowing consumers to see the contents without opening the package. This transparency enhances consumer confidence and helps in quick identification of the product. Additionally, blister packs offer superior protection against moisture, light, and contamination, ensuring product integrity and extending shelf life.

Applications and Industries

While predominantly used in the pharmaceutical sector, automatic blister packing machines have found applications in various other industries. They are extensively used for packaging over-the-counter medications, vitamins, and dietary supplements. The consumer goods industry utilizes blister packs for items like batteries, razors, and small electronics. In the food industry, blister packaging is employed for confectionery, chewing gum, and portion-controlled snacks. The versatility of blister packaging makes it an attractive option for products that require individual protection and convenient dispensing.

Exploring Strip Packing Machines

The Strip Packing Process

Strip packing machines, also known as sachet machines, operate on a different principle compared to blister packers. These machines create a continuous strip of sealed pockets, each containing a single dose or unit of the product. The process involves feeding two layers of packaging material (usually aluminum foil or plastic film) into the machine. The product is dispensed between these layers, which are then heat-sealed to form individual pockets. The resulting strip can be perforated for easy separation of individual units.

Benefits of Strip Packaging

Strip packaging offers several advantages that make it suitable for certain applications. It is highly efficient for high-volume production, capable of producing a large number of units in a continuous strip using an automatic blister packing machine. This packaging method is particularly cost-effective for small, uniform products like tablets or capsules. Strip packs are compact and easy to store, making them ideal for products that need to be carried in pockets or purses. The simplicity of the packaging also makes it easy for consumers to access the product by tearing off individual units.

Common Uses and Market Preferences

Strip packing is widely used in the pharmaceutical industry, especially for over-the-counter medications and prescription drugs that require daily dosing. It's particularly popular in regions where unit-dose packaging is preferred or mandated. Beyond pharmaceuticals, strip packaging is used for single-serve food items, powdered beverages, and some cosmetic products. In certain markets, particularly in developing countries, strip packaging is favored due to its affordability and ease of distribution in small quantities.

Comparing Automatic Blister Packing and Strip Packing Machines

Production Efficiency and Output

When comparing the efficiency of automatic blister packing machines and strip packing machines, several factors come into play. Blister packing machines typically offer more flexibility in terms of cavity sizes and shapes, allowing for a wider range of product types to be packaged. However, strip packing machines often have higher production speeds, making them more suitable for high-volume, uniform products. The choice between the two often depends on the specific production requirements and the nature of the product being packaged.

Product Protection and Shelf Life

Both packaging methods offer good product protection, but in different ways. Blister packs excel in providing a rigid barrier against physical damage and offer excellent moisture and oxygen protection when using appropriate materials. This makes them ideal for products sensitive to environmental factors. Strip packs, while offering good barrier properties, are more suitable for products that don't require rigid protection. The choice between the two often depends on the product's sensitivity to environmental factors and the desired shelf life.

Cost Considerations and Market Acceptance

The cost-effectiveness of each packaging method varies depending on factors such as production volume, packaging materials, and market preferences. Generally, strip packing can be more economical for high-volume production of small, uniform products. Blister packaging, while potentially more expensive per unit, offers advantages in terms of product presentation and consumer preference in certain markets. The decision between the two often involves balancing production costs with market demands and regulatory requirements in different regions.

Conclusion

Choosing between automatic blister packing machines and strip packing machines requires careful consideration of various factors including product characteristics, production volume, market preferences, and regulatory requirements. While blister packs offer superior protection and presentation, strip packs excel in efficiency and cost-effectiveness for certain applications. Understanding the strengths and limitations of each packaging method is crucial for making an informed decision that aligns with your production needs and market demands. As packaging technology continues to evolve, staying informed about the latest developments in both blister and strip packing machines will be key to maintaining a competitive edge in the pharmaceutical and consumer goods industries.

Contact Us

For more information on our range of packaging solutions, including automatic blister packing machines and strip packing machines, please contact us at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your specific needs.